Post date: Jun 2, 2023

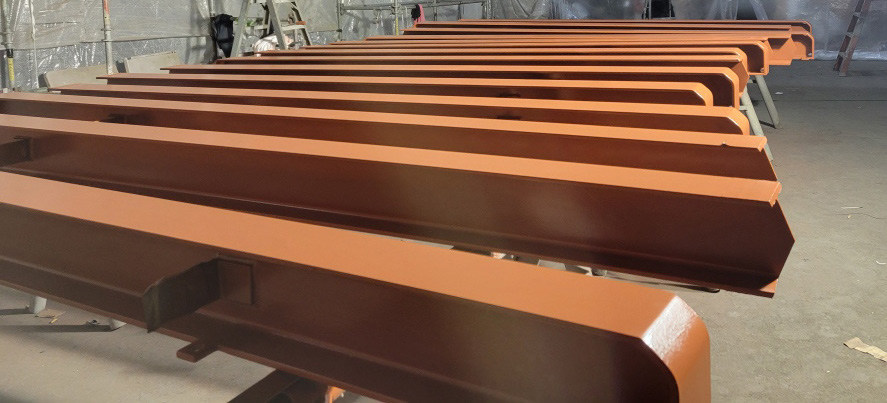

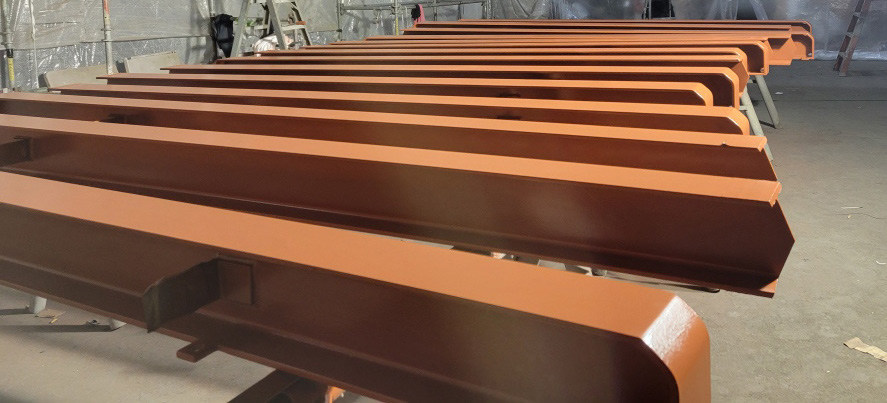

There are pieces of San Francisco’s Golden Gate Bridge at the Port of Pasco. Not oversized souvenirs, but actual parts to go on the bridge.

Port tenant Hancock Sandblast and Paint is working on an upgrade to the iconic bridge by sandblasting and then coating numerous pieces for its 1.7 mile span.

Hancock is one of only two companies approved by the Golden Gate Bridge, Highway and Transportation District to do this work, which includes matching the color specifically.

“The color is actually called International Orange, not golden, and they have visited our facility two times to ensure the quality of our work and the color match,” said Don Gammell, President.

The pieces are trucked from Vancouver to Pasco and on to California.

Work on the Golden Gate is just one of many major, and large, projects Hancock has undertaken.

The company started in the Tri-Cities 18 years ago and specializes in heavy and industrial work. Five years ago, it contracted to do a project for Little Goose Dam which required a large overhead crane and access to the Columbia River, both of which were available at the Port’s Marine Terminal. What was initially a short-term lease for the duration of the dam project has turned into a permanent location for the company.

“At the Port, we have a 30,000 square foot, climate-controlled sandblast and coating facility with a large 25-ton overhead crane. We have access to the river, which is utilized in some projects to get the big pieces to us. We also could have access to rail if we need it,” he said.

Through the years, the company has worked on projects for the U.S. Army Corps of Engineers and the Bureau of Reclamation, for numerous governmental agencies, for manufacturing companies, for Hanford contractors including the VIT Plant, and companies within the power industry.

Hancock can perform metalizing, fireproofing, plural component, wood installation, as well as your standard industrial or architectural epoxy, polyurethane coating. Some of the work, said Gammell, is removing the original lead paint and replacing it with an environmentally safe coating.

One of its recent projects included a 60,000-pound HUB from Priest Rapids dam.

“That is the size of some of the pieces we work on,” he said. The company has worked on projects throughout the country. It has even worked internationally by sandblasting and painting 260 roof arches for the world’s largest retractable fabric roof on the BC Place stadium in Vancouver, Canada.

For more information about Hancock, visit www.hsbpcoating.com.